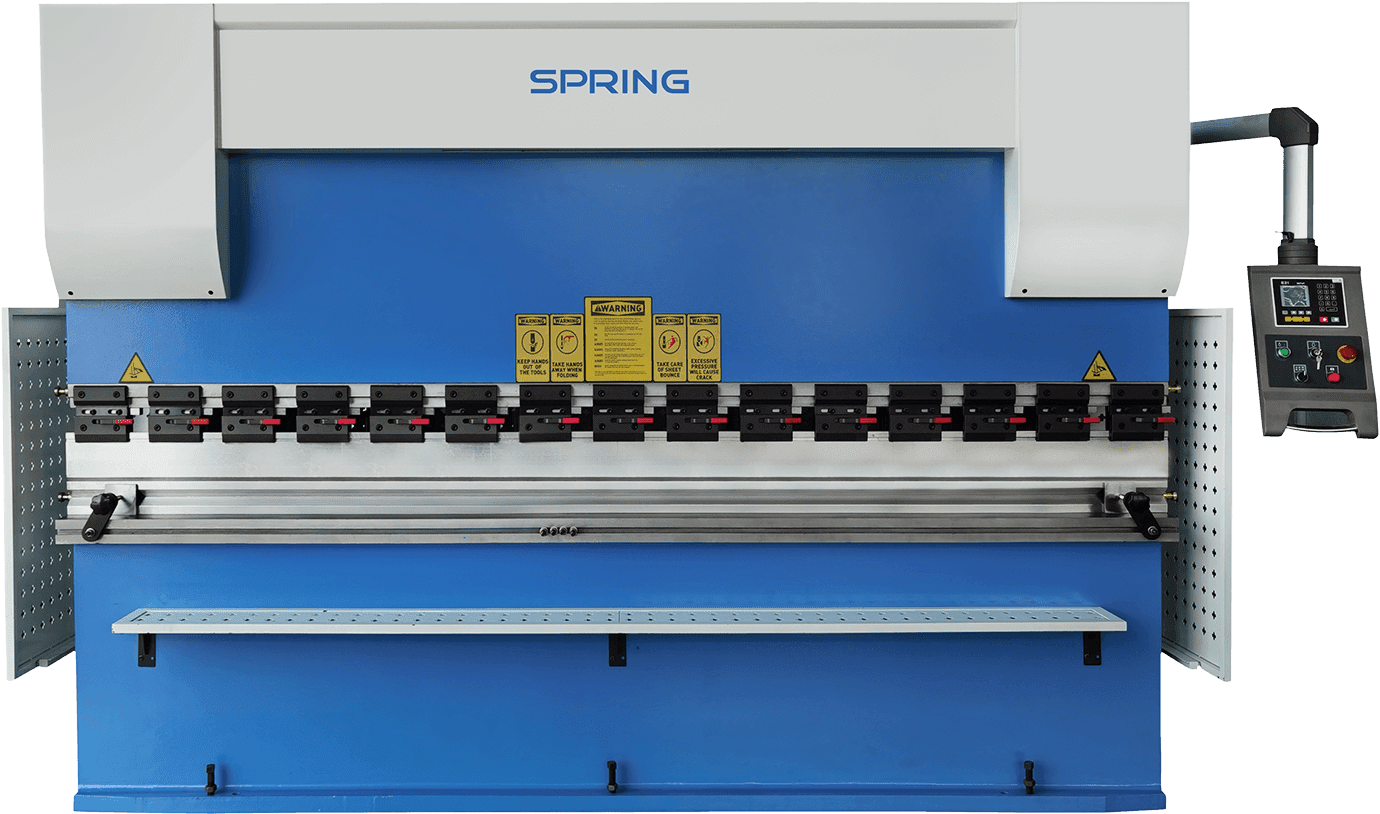

WC67Y Hydraulic press brake

Product details

WC67Y Hydraulic press brake

Elevate your metal fabrication game with our cutting-edge NC steel bending machine. Crafted for precision and efficiency, this advanced numerical control (NC) machine is engineered to meet the demands of modern metalworking projects. Whether you’re handling intricate designs or large-scale productions, our NC steel bending machine delivers unmatched performance.

Key Features

- Numeric Control Excellence: Experience precision like never before. Our NC steel bending machine is equipped with advanced numerical control technology, allowing for accurate and repeatable bends with minimal setup time. Achieve complex shapes and angles effortlessly.

- Versatile Bending Capabilities: Adaptability is at the core of our NC steel bending machine. From mild steel to stainless steel, this versatile machine accommodates a wide range of materials and thicknesses, making it ideal for diverse applications in various industries.

- Intuitive Programming: Effortlessly program and execute bends with the user-friendly interface. Our NC steel bending machine simplifies the programming process, reducing the learning curve and enabling operators to achieve optimal results with ease.

- High-Speed Performance: Boost productivity with high-speed bending capabilities. Our machine ensures quick and efficient processing, allowing you to meet tight deadlines and maximize throughput in your metalworking operations.

- Durable Construction: Built for longevity, our NC steel bending machine features a robust and durable construction. It withstands the rigors of heavy-duty use, providing reliable performance in demanding industrial settings.

- Space-Efficient Design: Maximize floor space with the compact and ergonomic design of our NC steel bending machine. It's engineered for efficiency without compromising on performance, making it a valuable addition to any metal fabrication workshop.

More features

- The whole machine is processed after the frame is welded to ensure its high strength, high rigidity and high precision.

- Mechanical forced synchronisation system is adopted to make both sides of the slider move parallel to each other through the synchronising shaft.

- Optional upper mould deflection compensation device, fast upper mould clamping device.

Machine Parameter

| Specification | Nominal pressure | Length of working table | Distance between uprights | Throat depths | Ram stroke | Open height | Motor power |

| kn | mm | mm | mm | mm | mm | kw | |

| WC67Y-63/2500 | 630 | 2500 | 2000 | 250 | 100 | 370 | 5.5 |

| WC67Y-63/3200 | 630 | 3200 | 2500 | 250 | 100 | 370 | 5.5 |

| WC67Y-80/3200 | 800 | 3200 | 2500 | 250 | 120 | 380 | 5.5 |

| WC67Y-100/3200 | 1000 | 3200 | 2500 | 320 | 120 | 400 | 5.5 |

| WC67Y-100/4000 | 1000 | 4000 | 3000 | 320 | 120 | 400 | 7.5 |

| WC67Y-125/3200 | 1250 | 3200 | 2500 | 320 | 120 | 400 | 7.5 |

| WC67Y-125/4000 | 1250 | 4000 | 3000 | 320 | 120 | 400 | 7.5 |

| WC67Y-160/3200 | 1600 | 3200 | 2500 | 320 | 180 | 450 | 7.5 |

| WC67Y-160/4000 | 1600 | 4000 | 3000 | 320 | 180 | 450 | 11 |

| WC67Y-160/6000 | 1600 | 6000 | 4100 | 320 | 180 | 450 | 11 |

| WC67Y-200/3200 | 2000 | 3200 | 2450 | 320 | 200 | 470 | 11 |

| WC67Y-200/4000 | 2000 | 4000 | 3000 | 320 | 200 | 470 | 15 |

| WC67Y-200/6000 | 2000 | 6000 | 4500 | 320 | 200 | 470 | 15 |

| WC67Y-250/3200 | 2500 | 3200 | 2450 | 400 | 250 | 540 | 15 |

| WC67Y-250/4000 | 2500 | 4000 | 3000 | 400 | 250 | 540 | 15 |

| WC67Y-250/6000 | 2500 | 6000 | 4600 | 400 | 250 | 540 | 15 |

| WC67Y-300/4000 | 3000 | 4000 | 3000 | 400 | 250 | 560 | 18.5 |

| WC67Y-400/4000 | 4000 | 4000 | 3100 | 400 | 250 | 560 | 18.5 |

| WC67Y-400/6000 | 4000 | 6000 | 4500 | 400 | 250 | 560 | 22 |

| WC67Y-500/4000 | 5000 | 4000 | 3100 | 500 | 250 | 600 | 30 |

| WC67Y-500/6000 | 5000 | 6000 | 4500 | 500 | 250 | 600 | 30 |

| WC67Y-600/8000 | 6000 | 8000 | 4500 | 500 | 300 | 650 | 45 |

| WC67Y-800/6000 | 8000 | 6000 | 4500 | 500 | 300 | 650 | 55 |

| WC67Y-1200/6000 | 12000 | 6000 | 4500 | 500 | 300 | 650 | 75 |

Main parts of our press brake

Programs

- Digital display E21 control

- 5.7-inch LCD screen up to 99 programs

All pipes are ferrules types or soft pipes,no welded pipes, avoid oil leakage

All our press brake machines are equipped with frequency converters to increase productivity, reduce energy consumption, improve machine accuracy and reduce damage to mechanical systems.

All electrical parts adopt international brand Schneider to ensure the stable operation of the machine.

Centralised oil supply saves time and improves work efficiency

Dedicated tool platform for user-friendly storage.

Bending machine rear guard to protect workers’ safety.

Front support with linear guide to hold sheet.

Standard bending tools (can be customized

Why Choose Spring CNC?

At SPRING CNC, we’re committed to providing cutting-edge solutions for your metalworking needs. Our press brake machines combine innovation, precision, and reliability, making them the ideal choice for businesses striving for excellence in metal fabrication.

Explore our range of press brake machines and elevate your metal bending capabilities today. Invest in efficiency, invest in SPRING CNC