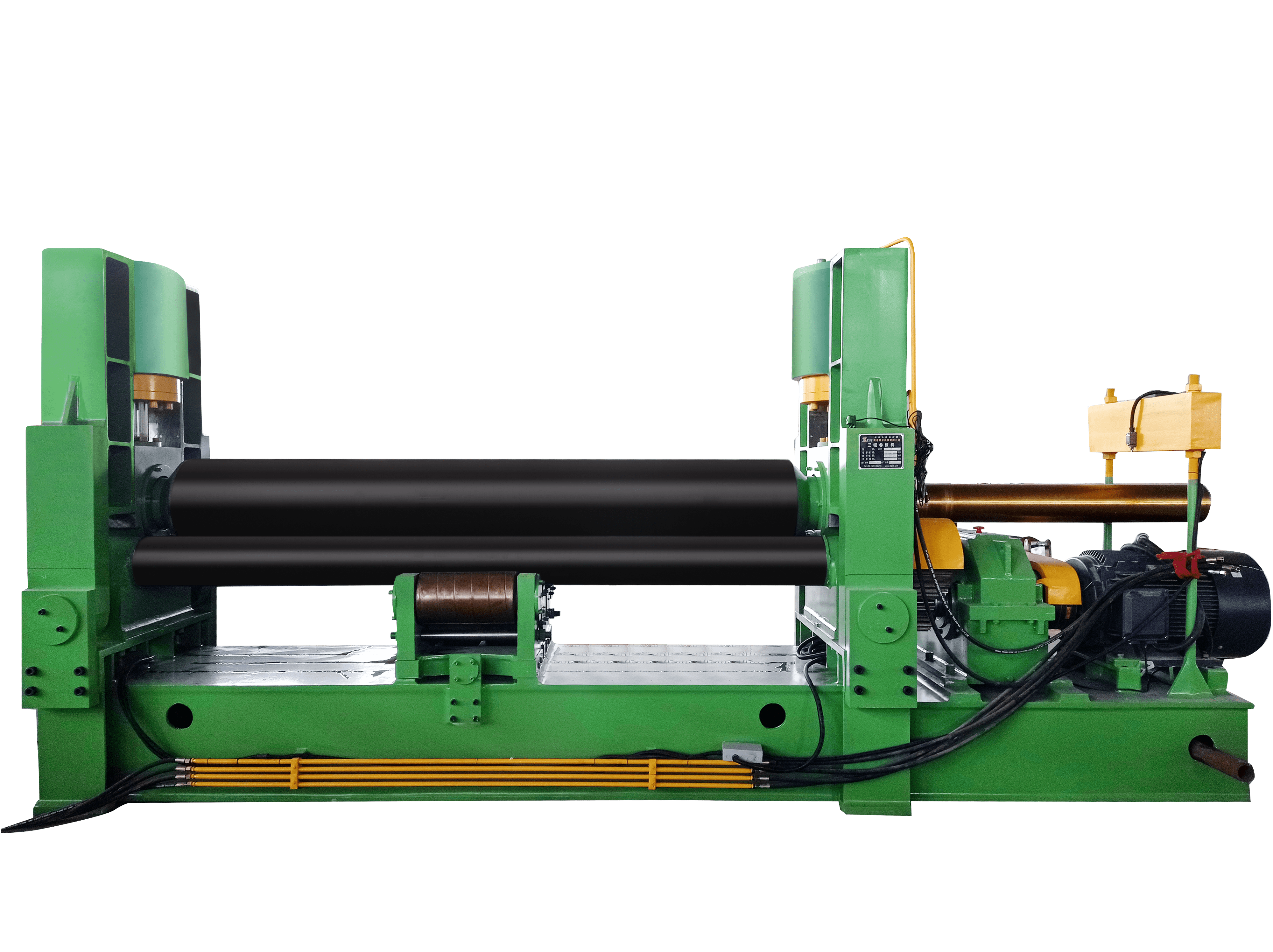

W11S 3 Roller Rolling Machine

Product details

W11S 3 Roller Rolling Machine

SPRING top-roller universal three-roller plate rolling machine is used for bending and rolling a certain thickness of metal plate into cylindrical, curved or tapered parts at room temperature. Its working principle is rotary bending deformation. Because the upper roller can be moved up and down, can also be moved horizontally, so there is no need to add additional equipment, can be loaded at a time, without adjusting the head can be completed at both ends of the plate pre-bending and molding bending function, as well as for the molding of the correction of the workpiece. With the aid of auxiliary devices, the end of the sheet can be aligned, and the remaining straight edge is less. It is a necessary equipment for the machine and equipment manufacturing industries such as petroleum, chemical, cement, shipbuilding, boiler, aviation, water conservancy, power transmission tower and so on.

Our three-roller plate rolling machine has the following features

- High-precision end pre-bending Free setting of straight edge length and direct pressurized pre-bending of the upper rolls can accomplish high-precision end pre-bending.

- Rounding is carried out by driving the two lower rolls through the electric motor and reducer.

- Since the elevation of the lower rolls is constant, it is easy to feed and operate

- paint surface is flat and bright, the thickness of the paint mold is uniform, and there are no defects such as flow marks and leakage of spray.

- Superior precision of products The upper roll is in the shape of a drum, and the lower part of the lower roll is adjusted with the help of a carrier roll, which is continuously bent, and can roll ideal products in a wide range from thin plates to thick plates.

- Safety of operation The two lower rolls are fixed, the upper rolls move up and down, left and right, and the workpiece does not move with the work rolls, so the operator is safe.

- Integral structure, simple foundation, easy to move The equipment adopts integral chassis, no need for ground bolts, simple foundation, easy to move the workplace.

- The electrics used in the equipment all adopt high-quality products of famous brand enterprises, and the electric protection devices (such as current relay, air switch, etc.) are strictly tested before installation, and reliable operation is guaranteed.

- Abundant bending shapes With rolling O-type, U-type, multi-section R, auxiliary cone device, can roll a certain range of cone. O-type bending: rear bending mode; U-type bending: front bending mode;

- Tipping frame adopts hydraulic tipping, faster speed

Main parameters

| Specification | Pressure on the upper roller (Tons) | Upper roller diameter (mm) | Lower roller diameter (mm) | Central distance (mm) | Motor power(kw) | ||

| Driving | Hydraulic | Shift | |||||

| W11S-12*2000 | 65 | 250 | 145 | 200 | 5.5 | 4 | 0.75 |

| W11S-16*2000 | 75 | 260 | 150 | 245 | 7.5 | 4 | 1.5 |

| W11S-16*2500 | 100 | 300 | 165 | 270 | 11 | 5.5 | 2.2 |

| W11S-20*2000 | 130 | 300 | 165 | 270 | 11 | 5.5 | 2.2 |

| W11S-20*2500 | 130 | 330 | 180 | 300 | 15 | 5.5 | 2.2 |

| W11S-20*3000 | 160 | 375 | 200 | 330 | 18.5 | 7.5 | 2.2 |

| W11S-25*2500 | 190 | 380 | 220 | 360 | 22 | 7.5 | 4 |

| W11S-25*3000 | 230 | 420 | 235 | 380 | 30 | 11 | 4 |

| W11S-25*3500 | 230 | 440 | 235 | 380 | 30 | 11 | 4 |

| W11S-30*2500 | 230 | 410 | 235 | 380 | 30 | 11 | 4 |

| W11S-30*3000 | 270 | 450 | 250 | 400 | 37 | 15 | 4 |

| W11S-30*3500 | 320 | 480 | 260 | 420 | 37 | 15 | 5.5 |

| W11S-30*4000 | 380 | 550 | 275 | 460 | 45 | 22 | 5.5 |

| W11S-35*2500 | 270 | 450 | 250 | 400 | 37 | 15 | 4 |

| W11S-35*3000 | 380 | 500 | 275 | 460 | 45 | 22 | 5.5 |

| W11S-40*2500 | 380 | 500 | 270 | 420 | 37 | 18.5 | 7.5 |

| W11S-40*3200 | 430 | 540 | 290 | 500 | 45 | 22 | 7.5 |

| W11S-40*3500 | 460 | 580 | 290 | 500 | 55 | 22 | 11 |

| W11S-40*4000 | 540 | 630 | 340 | 610 | 55 | 22 | 11 |

| W11S-45*2500 | 430 | 520 | 290 | 500 | 55 | 22 | 7.5 |

| W11S-45*3000 | 540 | 590 | 340 | 610 | 55 | 22 | 11 |

| W11S-45*4000 | 610 | 660 | 360 | 650 | 75 | 30 | 15 |