QC11Y Guillotine Shearing machine

Product details

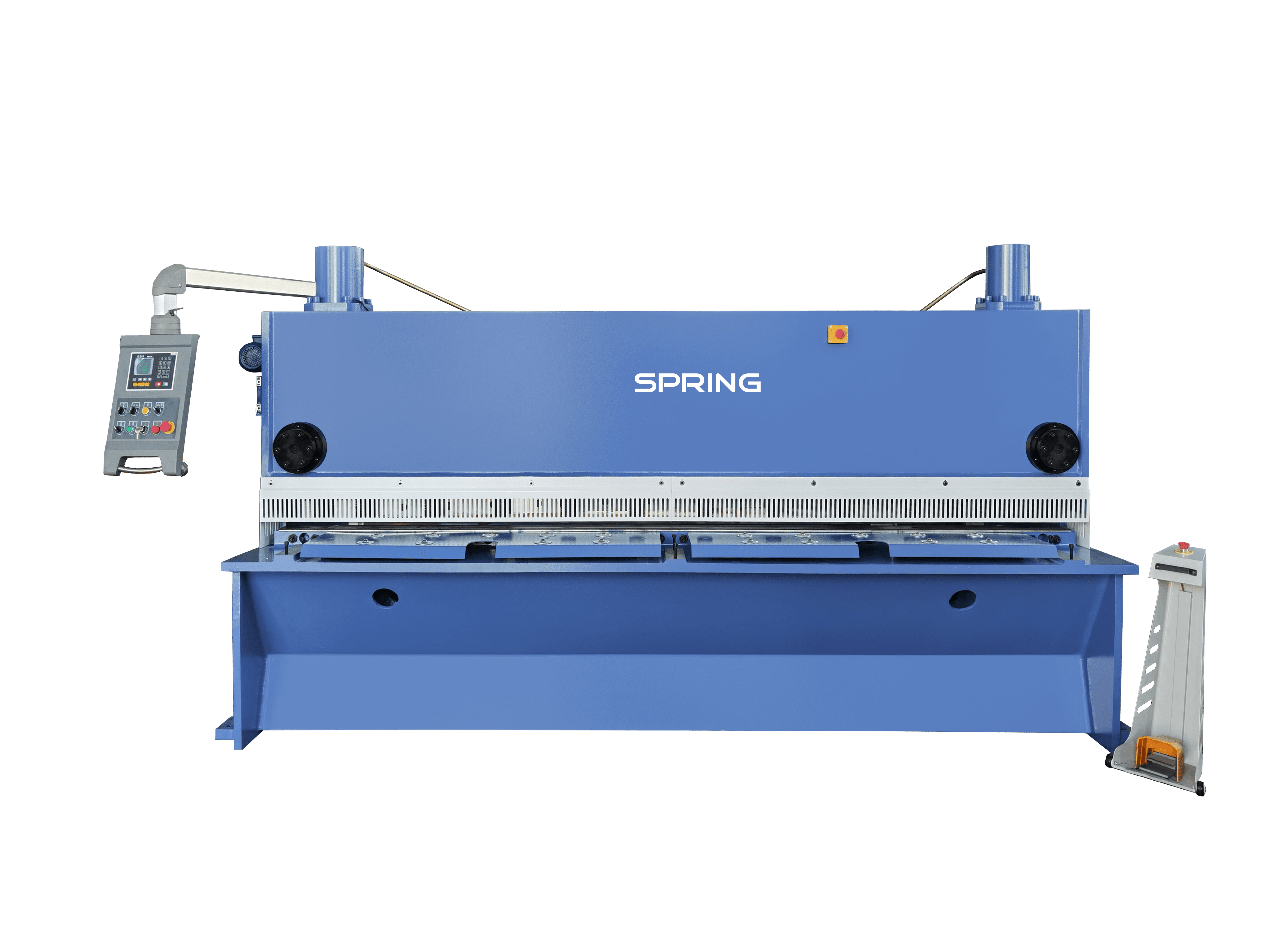

QC11Y Guillotine Shearing machine

Are you looking for a dependable hydraulic shear machine? Look no further than SPRING CNC. Our premium hydraulic guillotine shears deliver precise cuts with automatic blade gap and rake angle adjustments, ensuring optimal performance for your business needs. The QC11Y series hydraulic shears at SPRING cater to diverse industries, offering top-notch solutions. Explore our range of high-quality hydraulic guillotine shears below or reach out to SPRING for a complimentary quote on your next equipment investment!

Machine advantages

- Precision Cutting: Guillotine shears provide precise cutting accuracy, ensuring clean and straight cuts across various materials.

- Efficiency: With their powerful hydraulic systems and efficient blade designs, guillotine shears can handle large volumes of cutting tasks quickly and effectively, enhancing productivity in manufacturing operations.

- Safety Features:Our machines come with advanced safety guards and emergency stop mechanisms, also the light curtain to ensure a safe working environment for operators.

- Ease of Operation: Machines are designed for ease of use, with user-friendly controls and ergonomic features that make them accessible to operators of varying skill levels.

Machine Parameter

Specification | Shearing thickness(mm) | Shearing width(mm) | Strokes(mm¯¹) | Backgauge range(mm) | Shearing angle(°) | Main power(kw) |

QC11Y/K-4X2500 | 4 | 2500 | 8~16 | 20~600 | 30’~1°30′ | 5.5 |

QC11Y/K-4X3200 | 4 | 3200 | 8~16 | 20~600 | 30’~1°30′ | 5.5 |

QC11Y/K-6*2500 | 6 | 2500 | 8~16 | 20~600 | 30′~1°30′ | 7.5 |

QC11Y/K-6*3200 | 6 | 3200 | 8~16 | 20~600 | 30′~1°30′ | 7.5 |

QC11Y/K-6*4000 | 6 | 4000 | 8~16 | 20~600 | 30′~1°30′ | 7.5 |

QC11Y/K-6*5000 | 6 | 5000 | 8~16 | 20~800 | 30′~1°30′ | 11 |

QC11Y/K-6*6000 | 6 | 6000 | 8~16 | 20~800 | 30′~1°30′ | 11 |

QC11Y/K-8*2500 | 8 | 2500 | 8~16 | 20~600 | 30′~1°45′ | 11 |

QC11Y/K-8*3200 | 8 | 3200 | 8~16 | 20~600 | 30′~1°45′ | 11 |

QC11Y/K-8*4000 | 8 | 4000 | 8~16 | 20~600 | 30′~1°45′ | 11 |

QC11Y/K-8*5000 | 8 | 5000 | 8~16 | 20~800 | 30′~2° | 15 |

QC11Y/K-8*6000 | 8 | 6000 | 8~16 | 20~800 | 30′~2° | 15 |

QC11Y/K-12*2500 | 12 | 2500 | 8~12 | 20~800 | 30′~2° | 15 |

QC11Y/K-12*3200 | 12 | 3200 | 8~12 | 20~800 | 30′~2° | 15 |

QC11Y/K-12*4000 | 12 | 4000 | 8~12 | 20~800 | 30′~2° | 15 |

QC11Y/K-12*5000 | 12 | 5000 | 8~12 | 20~1000 | 30′~2° | 22 |

QC11Y/K-12*6000 | 12 | 6000 | 8~12 | 20~1000 | 30′~2° | 30 |

QC11Y/K-16*2500 | 16 | 2500 | 8~12 | 20~800 | 30′~2°30′ | 22 |

QC11Y/K-16*3200 | 16 | 3200 | 7~10 | 20~800 | 30′~2°30′ | 22 |

QC11Y/K-16*4000 | 16 | 4000 | 7~10 | 20~800 | 30′~2°30′ | 22 |

QC11Y/K-16*5000 | 16 | 5000 | 7~10 | 20~1000 | 30′~2°30′ | 30 |

QC11Y/K-16*6000 | 16 | 6000 | 7~10 | 20~1000 | 30′~2°30′ | 37 |

QC11Y/K-20*2500 | 20 | 2500 | 7~10 | 20~800 | 1°30′~3° | 30 |

QC11Y/K-20*3200 | 20 | 3200 | 6~10 | 20~800 | 1°30′~3° | 30 |

QC11Y/K-20*4000 | 20 | 4000 | 6~10 | 20~800 | 1°30′~3° | 30 |

QC11Y/K-20*5000 | 20 | 5000 | 6~10 | 20~1000 | 1°30′~3° | 37 |

QC11Y/K-20*6000 | 20 | 6000 | 6~9 | 20~1000 | 1°30′~3° | 37 |

QC11Y/K-25*2500 | 25 | 2500 | 6~9 | 20~800 | 1°30′~3°30′ | 37 |

QC11Y/K-25*3200 | 25 | 3200 | 6~9 | 20~800 | 1°30′~3°30′ | 37 |

QC11Y/K-25*4000 | 25 | 4000 | 6~8 | 20~1000 | 1°30′~3°30′ | 37 |

QC11Y/K-32*2500 | 32 | 2500 | 6~8 | 20~1000 | 1°30′~4° | 55 |

QC11Y/K-32*3200 | 32 | 3200 | 6~8 | 20~1000 | 1°30′~4° | 55 |

QC11Y/K-40*2500 | 40 | 2500 | 4~6 | 20~1000 | 1°30′~4° | 55 |

QC11Y/K-40*3200 | 40 | 3200 | 4~6 | 20~1000 | 1°30′~4° | 55 |

Main parts of shearing machine

Siemens motor guarantee the machine service life and improve the machine working stability.

Famous Germany Bosch hydraulic system hydraulic transmission with high reliability, integrated hydraulic system can effectively alleviate problems caused by leakage of hydraulic fluid.

Schneider electric elements makes machine stable operation.

Equipped with multiple switches, each component has a grounding device, with overload protection and short-circuit protection, safe and reliable, long service life, strong anti-interference ability, power off when opening the door, and the electrical cabinet is also equipped with a heat dissipation device.

Ball screw and linear guide rail.

Portable pedal switch ,smart feedback.

Numerical control system Estun E21

Control of ordinary motors or inverters, intelligent positioning, parameter backup or restoration with one key. 40 programmes are stored, each with 25 working steps.

Numerical control system Estun E200 (optional)

Fence type safety protection device,more safety and convenient.

Movable controller.

Standard machine with rear ramp for easy unloading.

Cutting angle adjustment by electric.

Rear machine guard with induction to protect workers’ safety.

Machine delivery

Why Choose Spring cnc?

At SPRING CNC, we’re committed to providing cutting-edge solutions for your metalworking needs. Our steel cutting machines combine innovation, precision, and reliability, making them the ideal choice for businesses striving for excellence in metal fabrication.

Explore our range of shearing machines and elevate your metal cutting capabilities today. Invest in efficiency, invest in SPRING CNC!