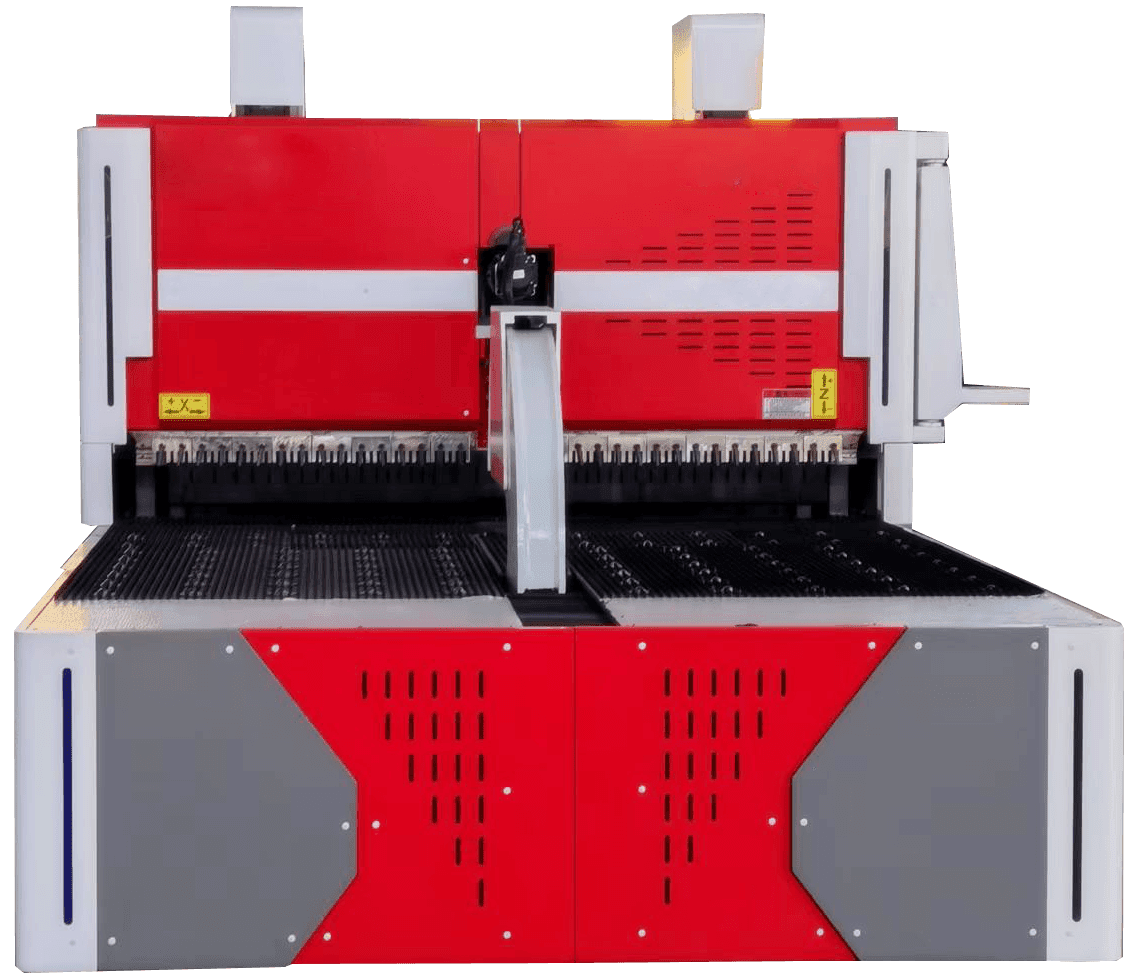

Panel bending machine

Product details

Panel bending machine

SPRING CNC panel bending machine is a high-tech product developed and produced for the sheet metal industry to improve productivity, reduce labor intensity and enhance corporate image. Our bending machine center can be widely used in the field of steel cabinet shells (file cabinets, tool cabinets, outer shrouds, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets ……), the field of kitchen utensils (refrigerators, air conditioners, stoves ……), furniture, ventilation, refrigeration, purification, door, decoration, elevator and other related metal forming fields.

The machine has the following features

- Industry 4.0 architecture, can be smoothly upgraded;

- Fast speed, only 0.2 seconds per cut, more than 3 times than ordinary CNC bending machines of the same specification;

- Rapid molding of workpieces with high consistency;

- High degree of automation, simple operation, low labor requirements;

- No need to make many molds, complex shapes (upward or downward folding of right angles, non-right angles, etc.) randomly designed at any time to produce; equipment equipped with a purely electric servo system, instead of hydraulic drive, with environmental protection, fast speed, high precision, maintenance-free and other advantages.

- Applicable to a wide range of materials, mainly stainless steel, cold rolled sheet, aluminum.

- Apply to a variety of loading and unloading methods: manual loading and unloading, truss robot loading and unloading, robotic arm loading and unloading are optional.

- Our CNC machining centers have a wealth of hardware and software interfaces, can be docked on the market conventional robotic arm, the specific selection can be selected according to the actual needs of the demand side.

- Control system realizes nine-axis (11-axis) concurrent linkage in the true sense, smooth bending action, high synergy of mechanical operation.

- It is equipped with bias load detection system, bias load follower system, thick plate detection system can effectively protect the machine, protect the workpiece, and reduce the waste of the workpiece.

- Cloud-based operation and maintenance management system can monitor the machine operation in real time.

- Human-machine interface is friendly, easy to understand and flexible programming

- For the size of non-standard workpiece, can be based on the shape of the workpiece can choose a different positioning datum, the shear error of the plate will be controlled in the first bending edge, to ensure that the size of the molding after the accuracy of the size.

- Easily realizes the sheet metal bending needs of arc, pressed dead edge, back type, closed type and other complex types.

Machine parameter

Model | SPR-1000 | SPR-1400 | SPR-2000 | SPR-2500 |

Feeding structure(mm) | 1000 | 1400 | 2000 | 2500 |

Max bending length(mm) | 170 | 170 | 170 | 170 |

Min bending height(mm) | 4 | 4 | 4 | 4 |

Min forming size(mm) | 200×120 | 110×140 | 110×140 | 110×140 |

Min forming size of single side(mm) | 120 | 110 | 110 | 110 |

Min arc radius(mm) | 1.2 | 1.2 | 1.2 | 1.2 |

Min continuous bending speed | 0.2s | 0.2s | 0.2s | 0.2s |

Bending angle (Degree) | 0-180 | 0-180 | 0-180 | 0-180 |

Control axis | 9 | 10 | 10-15 | 10-15 |

Max feeding speed(m/min) | 60 | 120 | 120 | 120 |

Max power(kw) | 16 | 22 | 25 | 32 |

Working table structure | Brush | Brush and universal ball | ||