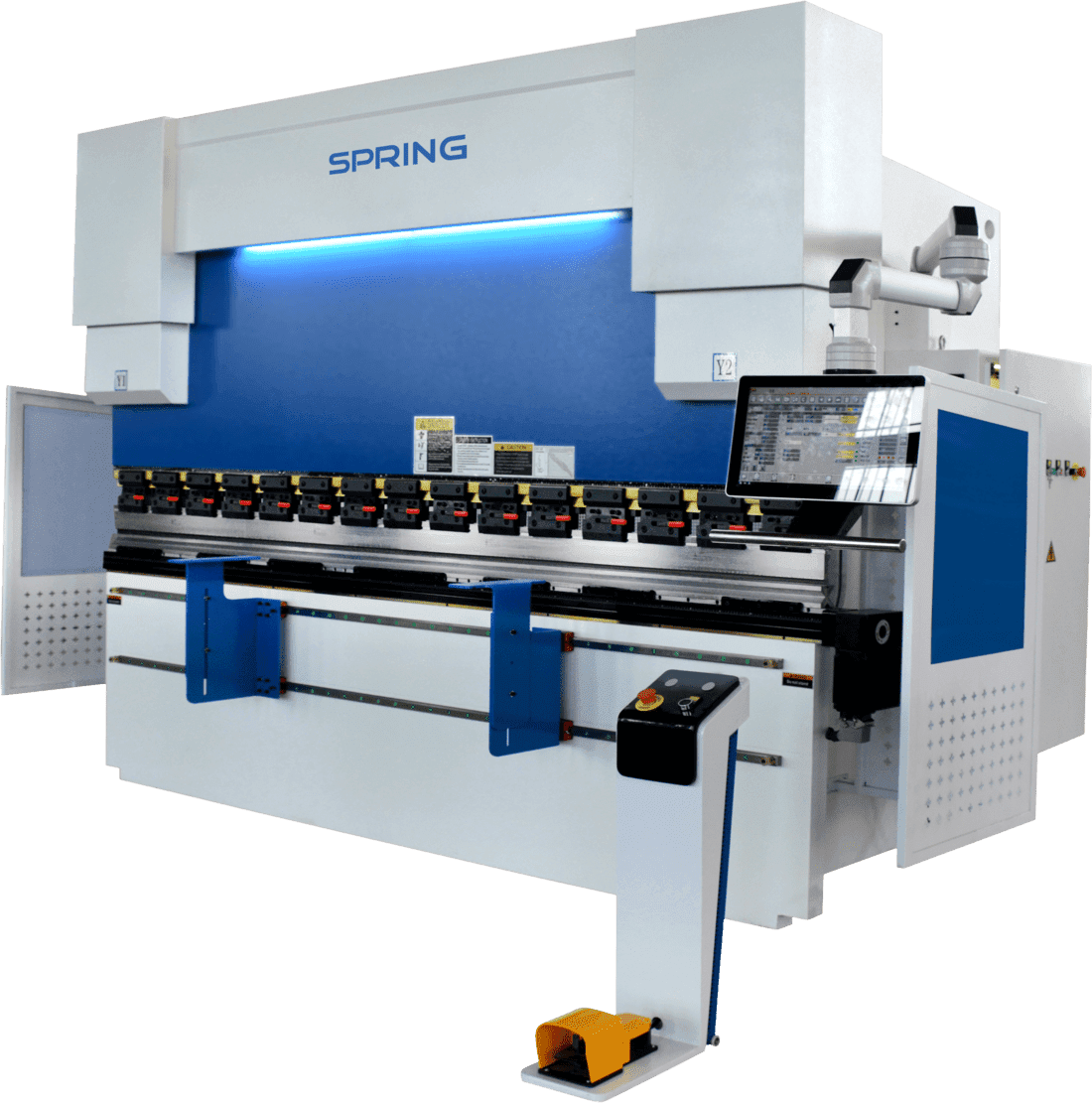

CNC Press Brake

Product details

Precision Press Brake Machines for Efficient Metal Bending

Unlock unparalleled precision and efficiency in metal bending with our state-of-the-art press brake machines. Engineered with cutting-edge technology, our press brakes redefine metalworking standards, ensuring accuracy and versatility for a wide range of applications.

Our press brake advantages:

- Precision Bending: Our press brake machines are equipped with advanced control systems, allowing for precise bending angles and consistent results. Achieve the accuracy your projects demand with every bend.

- Versatile Applications: From thin sheets to thick plates, our press brakes handle a variety of materials and thicknesses. Adaptability is key, and our machines provide the flexibility needed for diverse metalworking projects.

- User-Friendly Interface: Experience ease of operation with user-friendly interfaces. Intuitive controls make setting up, adjusting, and executing bends straightforward, reducing downtime and optimizing workflow.

- Robust Construction: Built with durability in mind, our press brakes feature robust frames and components. They withstand heavy-duty usage, ensuring longevity and reliability in your metal fabrication processes.

- Efficient Workflow: Boost your shop's productivity with efficient workflow integration. Our press brake machines seamlessly integrate into your existing production processes, enhancing overall efficiency.

- Safety First: Prioritize operator safety with our press brakes' comprehensive safety features. From emergency stop systems to safety guards, we ensure a secure working environment without compromising productivity.

Key features:

- Y1,Y2, X R CNC 4 axis control

- ±0,03 accuracy SERVO motorized back gauge X=600 mm

- Quick clamp punch tool holder

- Sliding front sheet support arms

- GIVI optic linear scales

- European type bottom table

- Motorised crowning compensation worktable (L≥1500mm )

- Standard 1 set of punch tools and die tools

Machine Parameter

| Specification | Nominal pressure | Length of working table | Distance between uprights | Throat depths | Ram stroke | Open height | Motor power |

| kn | mm | mm | mm | mm | mm | kw | |

| WE67K-63/2500 | 630 | 2500 | 2000 | 250 | 100 | 370 | 5.5 |

| WE67K-63/3200 | 630 | 3200 | 2500 | 250 | 100 | 370 | 5.5 |

| WE67K-80/3200 | 800 | 3200 | 2500 | 250 | 120 | 380 | 5.5 |

| WE67K-100/3200 | 1000 | 3200 | 2500 | 320 | 120 | 400 | 7.5 |

| WE67K-100/4000 | 1000 | 4000 | 3000 | 320 | 120 | 400 | 7.5 |

| WE67K-125/3200 | 1250 | 3200 | 2500 | 320 | 120 | 400 | 7.5 |

| WE67K-125/4000 | 1250 | 4000 | 3000 | 320 | 120 | 400 | 7.5 |

| WE67K-160/3200 | 1600 | 3200 | 2500 | 320 | 180 | 450 | 11 |

| WE67K-160/4000 | 1600 | 4000 | 3000 | 320 | 180 | 450 | 11 |

| WE67K-160/6000 | 1600 | 6000 | 4100 | 320 | 180 | 450 | 11 |

| WE67K-200/3200 | 2000 | 3200 | 2450 | 320 | 200 | 470 | 15 |

| WE67K-200/4000 | 2000 | 4000 | 3000 | 320 | 200 | 470 | 15 |

| WE67K-200/6000 | 2000 | 6000 | 4500 | 320 | 200 | 470 | 15 |

| WE67K-250/3200 | 2500 | 3200 | 2450 | 400 | 250 | 540 | 15 |

| WE67K-250/4000 | 2500 | 4000 | 3000 | 400 | 250 | 540 | 15 |

| WE67K-250/6000 | 2500 | 6000 | 4600 | 400 | 250 | 540 | 18.5 |

| WE67K-300/4000 | 3000 | 4000 | 3000 | 400 | 250 | 560 | 18.5 |

| WE67K-400/4000 | 4000 | 4000 | 3100 | 400 | 250 | 560 | 22 |

| WE67K-400/6000 | 4000 | 6000 | 4500 | 400 | 250 | 560 | 30 |

| WE67K-500/4000 | 5000 | 4000 | 3100 | 500 | 250 | 600 | 30 |

| WE67K-500/6000 | 5000 | 6000 | 4500 | 500 | 250 | 600 | 30 |

| WE67K-600/8000 | 6000 | 8000 | 4500 | 500 | 300 | 650 | 45 |

| WE67K-800/6000 | 8000 | 6000 | 4500 | 500 | 300 | 650 | 55 |

| WE67K-1200/6000 | 12000 | 6000 | 4500 | 500 | 300 | 650 | 75 |

Main Parts

Crowning System

The crowning system on the press brake enables to offset the possible deformations automatically while bending. And the bending angle is constant along the entire workpiece.

Sunny Hydraulic Gear Pump

- No noise and high-pressure design

- Long lifetime

High quality Hydraulic Servo Proportional Valve

Imported from Germany, the frequency response is higher and failure rate is lower, and the machine is running higher and stable.

Fast Clamp

Front Carrier

The movable front supporting device can dock at any position to assist your bending work.

Quick clamps and front support

The fast clamp could ensure the safe and fast punch changing, improving working efficiency. The movable front supporting device can dock at any position to assist your bending work.

X BackGauge

- Hiwin Ball screws and linear guide on X axis.

- Axis X speed 600 mm/s.

- Manual Z1, Z2-axis with HIWIN linear guide

- Mechanical accuracy t 0.01 mm.

- Fingers with double stop and micrometric adjustment

Safety guard side and back side to protect worker’s safety.

Standard Controller with machine Delem DA53T controller.

- "Shortcut key" touch navigation

- 10.1 "high resolution true color TFT display

- Up to 4 axes control (Y1, Y2 + 2 auxiliary axes)

- Deflection compensation control

- With mold / material / product library

WILA has focused on the R&D of the hydraulic clamping systems andsupporting tools of press brake machine for many years, and its quality andservice are trustworthy.

Other controllers are available

ITALY ESA630 Control

- Real -time automatic inspection formula programming mode, direct angle programming, automatic calculation of the R -axis position

- Automatic computing machinery compensation A axis position

- 2D graphics edit and model, preview workpiece, programming

- Automatic calculation bending process

- Manual bending page (single step, not interrupted program)

- All programs and parameters can be stored in the memory of this machine and copied to the mobile storage device

- Provide complete offline programming software

DELEM DA66T Control

- 17 -inch infrared touch screen (resolution 1280x1024)

- Windows CE operating system, storage capacity 1GB

- Standard 2D graphics, 3D display, optional 3D graphic programming

- Standard automatic bend sequence calculation

- Standard offline software

Cybelec touch 12 screen

- 12 -inch resistor touch screen

- "EasyBend" page easily performs single bending processing

- Interactive pop -up alarm message box

- Automatically calculate the bending angle, main pressure and deflection compensation

- Multiple automatic calculation functions of bending steps

- Store multiple bending steps and product angle, pressure and compensation control

- Finger drawing workpiece on screen

CYBELEC VT-19 Control From Switzerland

- 19 -inch capacitor touch screen (resolution 1366x768)

- Windows operating system, storage capacity 32GB

- Standard 2D graphics, optional 3D graphics

- Standard 4+1 axis, which can be equipped with an unlimited axis

- Standard automatic bend sequence calculation

- Support offline software (optional)

Optional Features

Up to 8 axis back gauge control

CNC automatic sheet Follower

Front two side laser safety device

Air cooler for tropical area user

Robotic Arm to improve productivity

Why Choose Spring Cnc?

At SPRING CNC, we’re committed to providing cutting-edge solutions for your metalworking needs. Our press brake machines combine innovation, precision, and reliability, making them the ideal choice for businesses striving for excellence in metal fabrication.

Explore our range of press brake machines and elevate your metal bending capabilities today. Invest in efficiency, invest in SPRING CNC